TESTS DURING PRODUCTION AND INSPECTIONS

Adequate verification at the various stages of production guarantees the quality of the product. The internal development of production test methodologies also guarantees the reduction of the same production cost because the tests are adapted to our production processes.

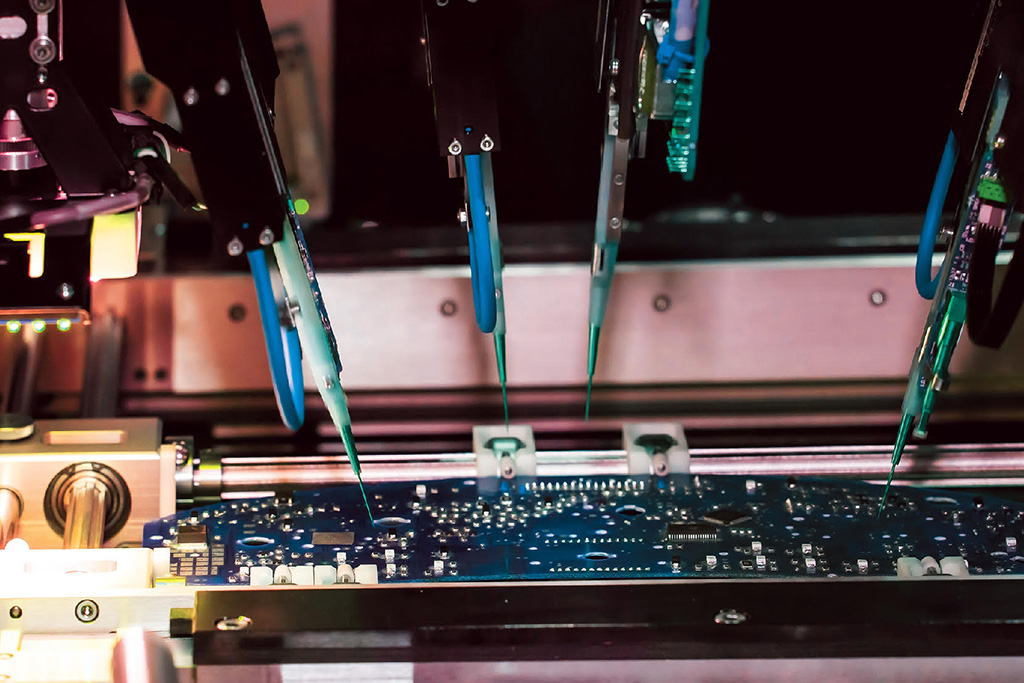

OUR ASSEMBLY LINES

- Loader

- Screen Print machine

- Complete with inspection of the solder paste

- Pick and place

- Forced air reflow soldering oven

- Vapor Phase

- AOI Inspection

CONTROLS

- X-RAY Machine

- BGA Rework Station

SMT

SMT (Surface Mount Technology) allows the mounting of electronic components on the printed circuit board without the need to drill holes and offers multiple advantages including:

- significant reduction in component sizes, resulting in smaller board sizes

- maximum automation and speed of assembly procedures

- no waste due to the need to cut excess rheophores

- the components can be mounted on both sides of the printed circuit board and this does not exclude the possibility of assembling boards in the two technologies of SMT and PTH together.

Each phase of the SMT soldering process is monitored and validated through control instrumentation, by verifying the correct deposit of the solder paste, by AOI (Automatic Optical Inspection) that ensures the quality of the solder application and the correct positioning of the components. We also have X-RAY inspection machines for checking using images of the solder balls (this process is carried out on a sample or on 100% of production)

THT

THT (through-hole or through-hole technology) is the technology in which the pins and rheophores of the components are inserted into the holes in the printed circuit board and soldered on the opposite side of the board, which EBV SRL implements as follows:

- Preforming components and automatic and non-automatic insertion of the same

- Laser soldering

- Wave soldering

- Manual soldering with trained personnel and ESD workstations

- Processes controlled by Visual Inspection and AOI (Automatic Optical Inspection)

Footer

EBV Srl

Viale Mazzini, 12

36100 Vicenza ( Italy )

P.IVA 04210670248

+39 0444 1231793

info@ebvelettronica.com